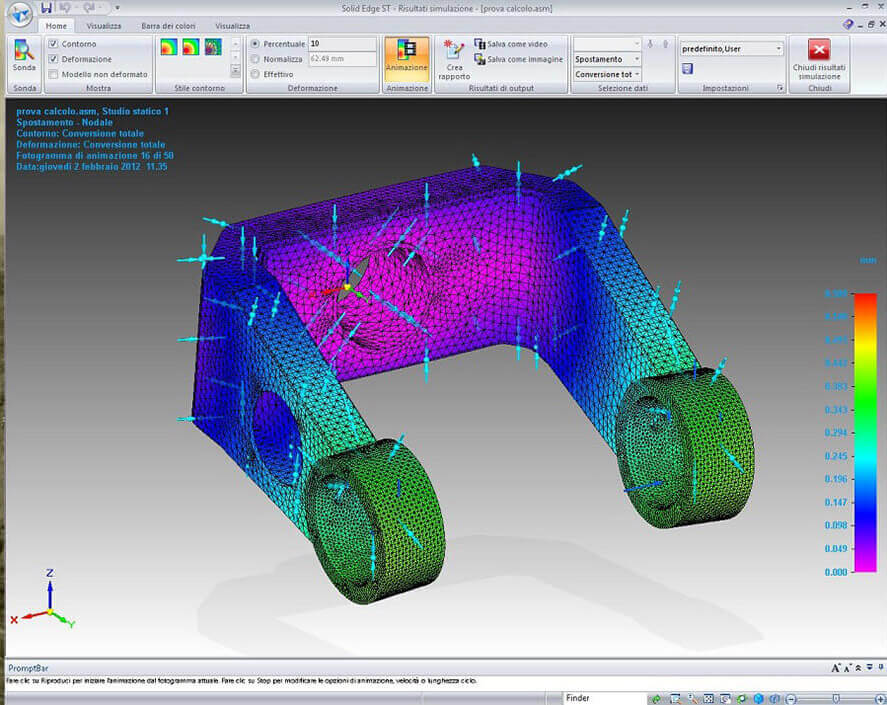

The ability to innovate of Proteco originates from the synergy between a precise knowledge of all the issues related to the manufacture of transposed cable and a remarkable inventive capacity level. In dimensioning and designing machinery, Proteco makes use of the most evolute technical means, including 3D prototypization. This methodical approach ensures the products to be at high grade of safety and reliability.

Many patents and related applications belong to Proteco, confirming the high level of competence in its specific field of activity. Our company owns today the more advanced technology in CTC field.

Most of Proteco's activities are focused on research and development. Our task is to continuously improve our machines by introducing the most advanced production technologies, which are essential to increase productivity with subsequent long-term economic growth.

Proteco pays special attention to the following main points:

• energy conservation – each machine is accurately designed to promote energy conservation and reduce the consumption of electricity

• safety - each device is equipped with the necessary safety mechanisms in accordance with the requirements of European legislation. In addition, Proteco provides the design of fences and optical barriers for the safety of the operators, like barriers for the space around the stranding cage

• productivity - the production line of Proteco is controlled by the operator through the main control panel. Even complex actions as, for example, loading and unloading of the stranding cage are performed by means of a semi-automatic manipulator

• low maintenance - all the components of the machines of Proteco are finely dimensioned at the design stage in order to be more resistant to wear and tear remote assistance - the control panel is equipped with wireless and Ethernet connections for tele-assistance from Proteco.